I lifted the Jeep using 44044 Rancho springs in the spring of 2004. My intent was to put 37" MTR's on it, which I did. So no problem, right? Well, sort of...it wheels great, I love the MTR's and the additional clearance and it runs better on the road too. The problem is that as soon as I put the bigger tires on I started breaking steering components. First I broke a pitman arm (in half!) in Buck Island Lake. Then I bent a pitman arm on Barrett. Then a steering box mount and a drag link. Though it wasn't stock (braced box and 1" DOM links with 3/4 ton TRE's), obviously the steering wasn't up to the chore.

So I started doing some research and decided to go to the following components in Spring of 2005:

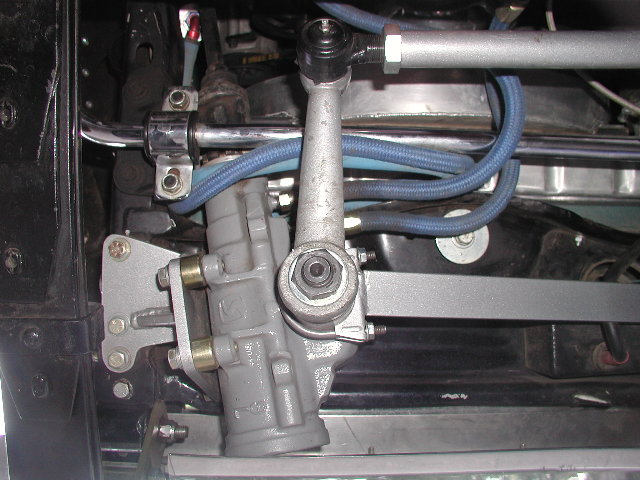

- Howe pump, steering box, reservoir, and steering assist ram

- Howe pump, steering box, reservoir, and steering assist ram

- Extreme Gear high steer arms, replacement drilled and tapped knuckles

- Extreme Gear high steer arms, replacement drilled and tapped knuckles

- 1" DOM tie rod and drag link with 1 ton tie rod ends

- 1" DOM tie rod and drag link with 1 ton tie rod ends

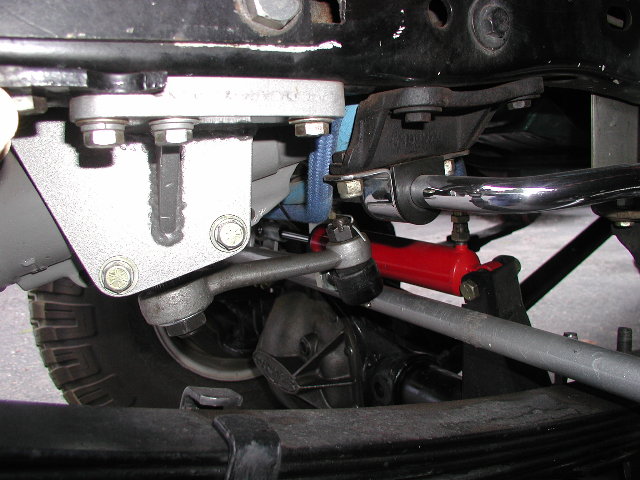

- Custom fabbed steering box mount to move the steering box forward

- Custom fabbed steering box mount to move the steering box forward

- New Teaberry hoses

- New Teaberry hoses

- A re-clocked Wagoneer pitman arm (longer and stronger)

- A re-clocked Wagoneer pitman arm (longer and stronger)

I didn't take pics as I went along, so all I have are pics of the completed project. Here they are:

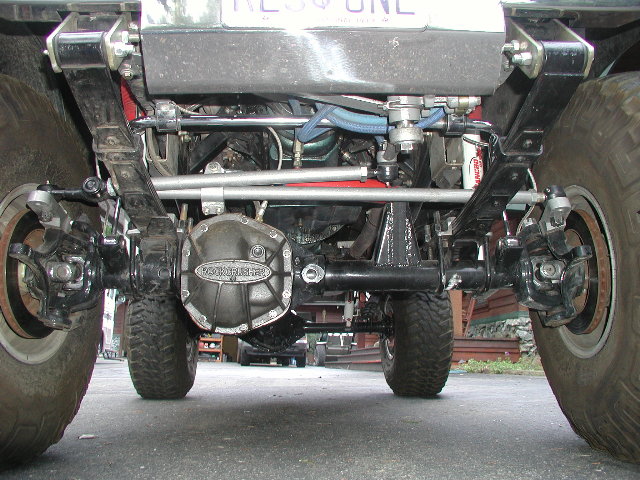

This is a shot of the completed steering. It steers better on the street, stays aligned, is up out of the way of the rocks, and best of all, doesn't break anymore.

From just behind the front end. This shows the ram mount at the axle and tie rod. In order to be effective, it is important that the ram be mounted as close to paralell to the tie rod as possible, so the ram mount is 8" tall. This creates a fair amount of leverage, so I used 2" .250 wall square tube and welded in triangular gussets on either side.

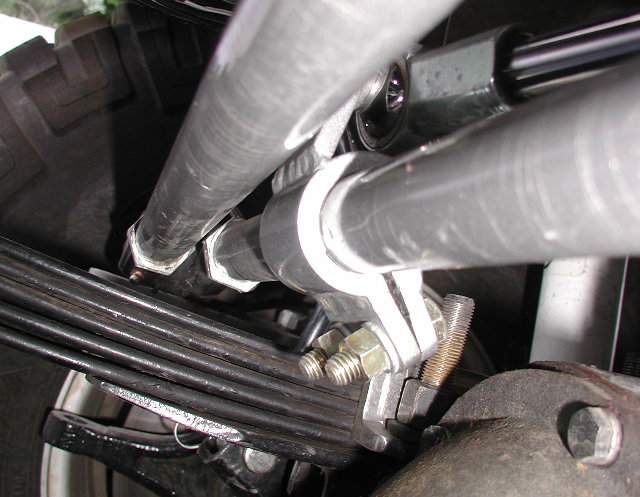

This shows the clamp on the other end of the ram. Instead of welding tabs to the tie rod, I chose to build this clamp. Now when I want to align the front end, I can loosen the clamp and turn the drag link without having to unbolt it. It also makes alignment and placement of the ram easy to adjust.